Cooperage - Funds

Automatic drilling and thread-whirling machine

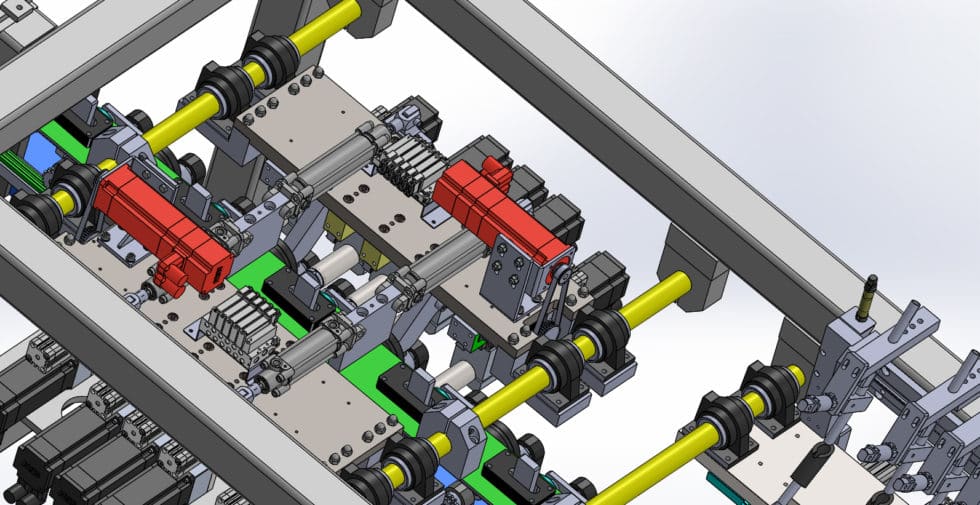

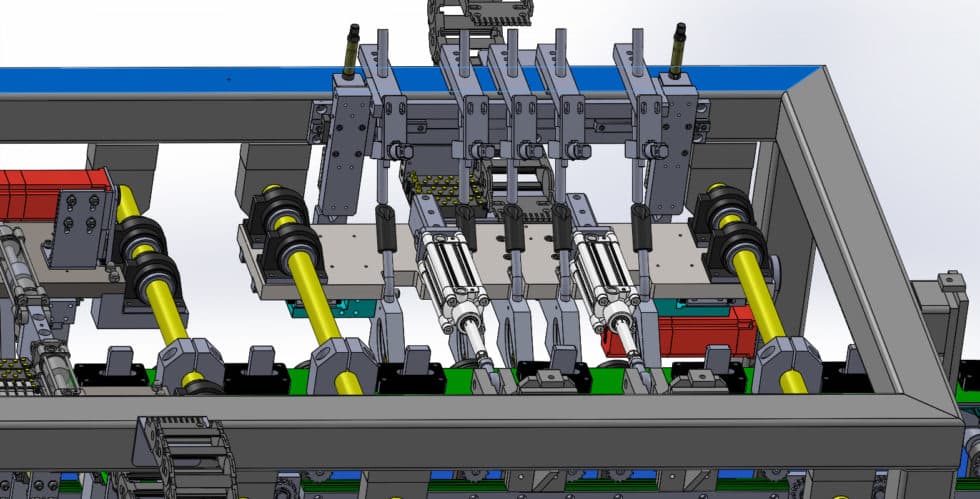

Automated thread-whirling line.

Cadence 5 seconds each.

For backplanes:

- max. thickness 40mm,

- minimum thickness 22mm,

- maximum width 120mm,

- minimum width 35mm,

- max. length 900mm,

- minimum length 350mm.

Line composed of:

Load installation (depending on your layout and requirements)

- motorized conveyor,

- digitized separator.

Drilling:

- digitized drill heads with brushless motors,

- five drill heads per side,

- maximum drilling diameter 9 mm,

- drill bit quick-release system,

- programmable and variable centre-to-centre distance depending on floor type,

- drilling position on adjustable base thickness,

- check drilling position,

- pneumatic drilling with position control.

Thread-whirling:

- vibratory trunnion feeder bowl,

- distributor,

- pneumatic pusher,

- pusher positioning control,

- variable center distance depending on drilling.

Output transfer (according to your needs):

- reconstitution of the bottom without assembly,

- bottom transfer or stacking.

Automation:

- touch screen,

- a program for each type of background,

- parts counter,

- fund counter,

- cycle time display,

- display any type of stop (lack of funds, blockage, cycle stop, set-up time, fault, etc.),

- possibility of remote control.

For more information, contact Amas.

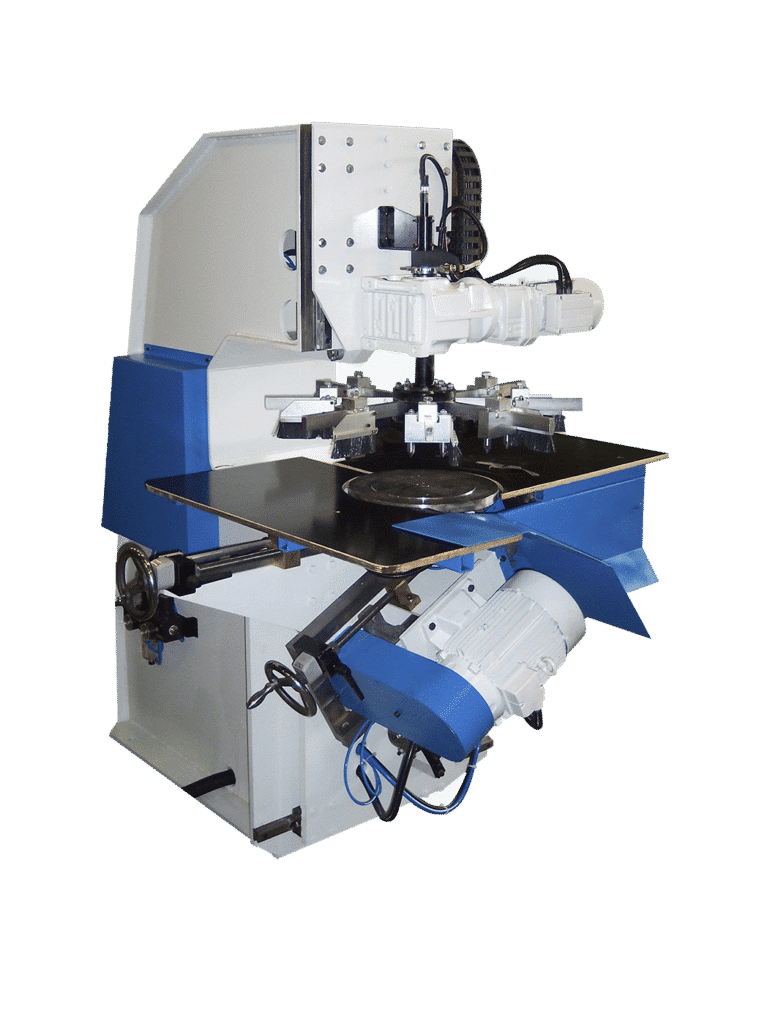

Bottom cutter

Semi-automatic bottom cutter

Equipment description:

- mechanically welded frame,

- pneumatic press,

- bottom rotation by geared motor,

- variable rotation speed,

- bottom with possible ovalization up to 12mm,

- manual adjustment by handwheel and value display,

- 7.5Kw motor spindle,

- pneumatic inclination,

- aluminum-frame cabin.

Option:

- Waste evacuation conveyor.

For more information, contact Amas.