Cooperage - Trimming and Drilling

Manual trimmer

Manual double trimmer

Standard machine 500-liter max. drum (can be modified on request)

- welded and machined frame,

- rail guidance and ball bearing carriage,

- hydraulic barrel clamping,

- drum rotation by geared motor,

- spindle brake motor 5.5Kw,

- adjustable drum rotation speed,

- tool movement by means of handwheel,

- Aluminum crowns.

Options:

- drum lift system for insertion into trimming machine,

- level with the barrel,

- ejector.

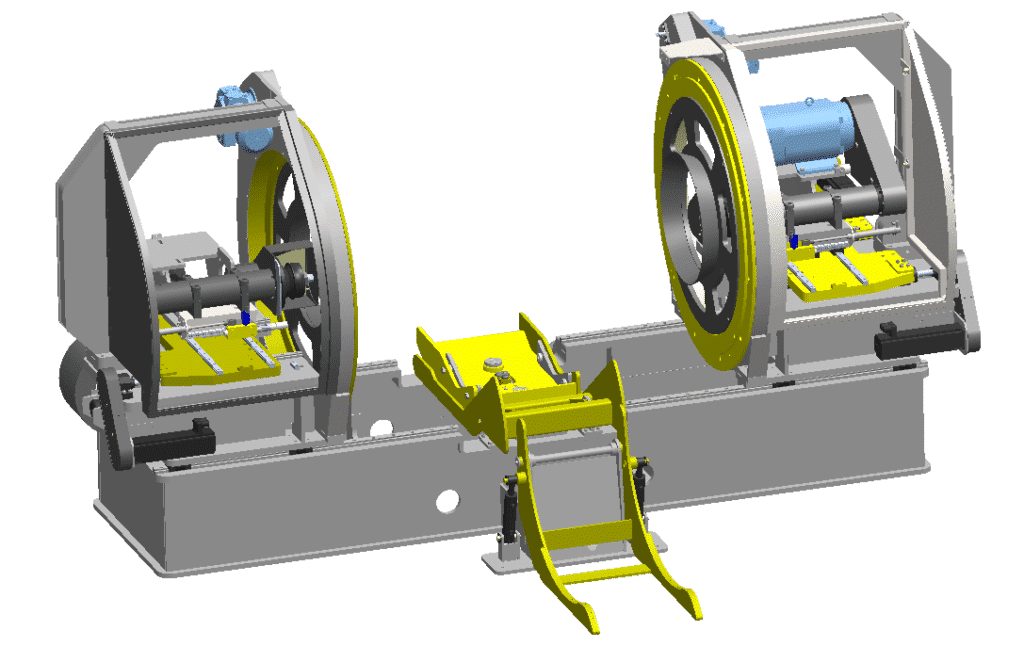

Automatic trimmer

Automatic double trimmer

Standard machine 600-liter max. drum (can be modified on request)

- in-cab trimmer,

- machined welded frame,

- guidance of all movements on rails and ball-bearing carriages,

- clamping by brushless geared motor (variable speed torque control),

- Brushless motorized tool movement,

- measurement of barrel length by digital probe,

- barrel length control,

- machining optimization,

- drum rotation on ball bearings and brushless motorization,

- variable rotation speed,

- crown shaft stripping system.

Option:

- drum lift system for insertion into trimming machine,

- level with the barrel,

- ejector,

- drilling cauterization.

For more information, contact Amas.

Bung hole cutting and drilling machine

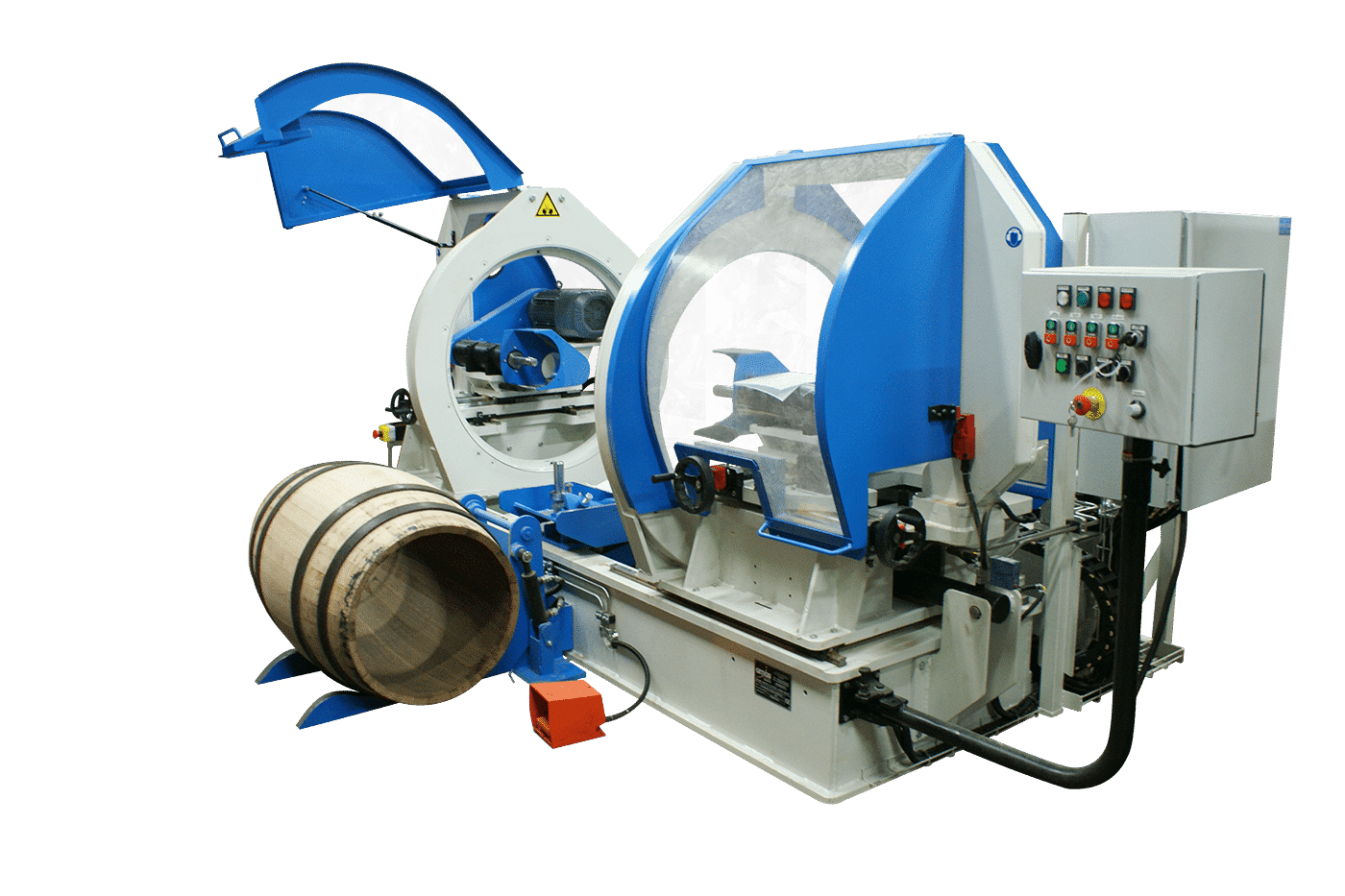

Double automatic trimming machine with cauterized drilling

Features identical to the 600-liter automatic trimming machine:

- in-cab machine,

- soundproof cabin.

Cauterized drilling system.

Measurement moves:

- diameter measurement moves with each barrel in the trimming cycle,

- digital measurement by encoder cylinder.

Drilling:

- detection of drilling position during trimming cycle,

- bunghole drilling according to drill bit size and shape,

- adjustable drill rotation speed,

- adjustable drilling speed,

- adjustable drilling diameter.

Cauterization:

- stainless steel heating cone,

- one cone per corner,

- heating temperature setting,

- cauterization diameter setting,

- 30° cone rotation.

Option:

- tool-free drill bit change via pneumatic clamping system,

- quick change of cone by pneumatic clamping,

- check tooling consistency (drill, cone, crowns and tools).

For more information, contact Amas.